Let’s discuss the question: how to hold round stock for milling. We summarize all relevant answers in section Q&A of website Achievetampabay.org in category: Blog Finance. See more related questions in the comments below.

How do you hold a round part for milling?

One way of holding a round bar in a vice is to use a spacer between the round part and one face of the vice with a V-shape in it. It is very probable that you will need a set of these because one that holds the biggest round shape will be too big for small round shapes.

How do you clamp a round stock?

Take the rubber from a bicycle’s interior or just any rubber that can do the job. Secure the parts of a round object that has split in two, apply wood glue in between the pieces, and then join them. Apply the rubber band outside while stretching it so out pressure, as what clamps do.

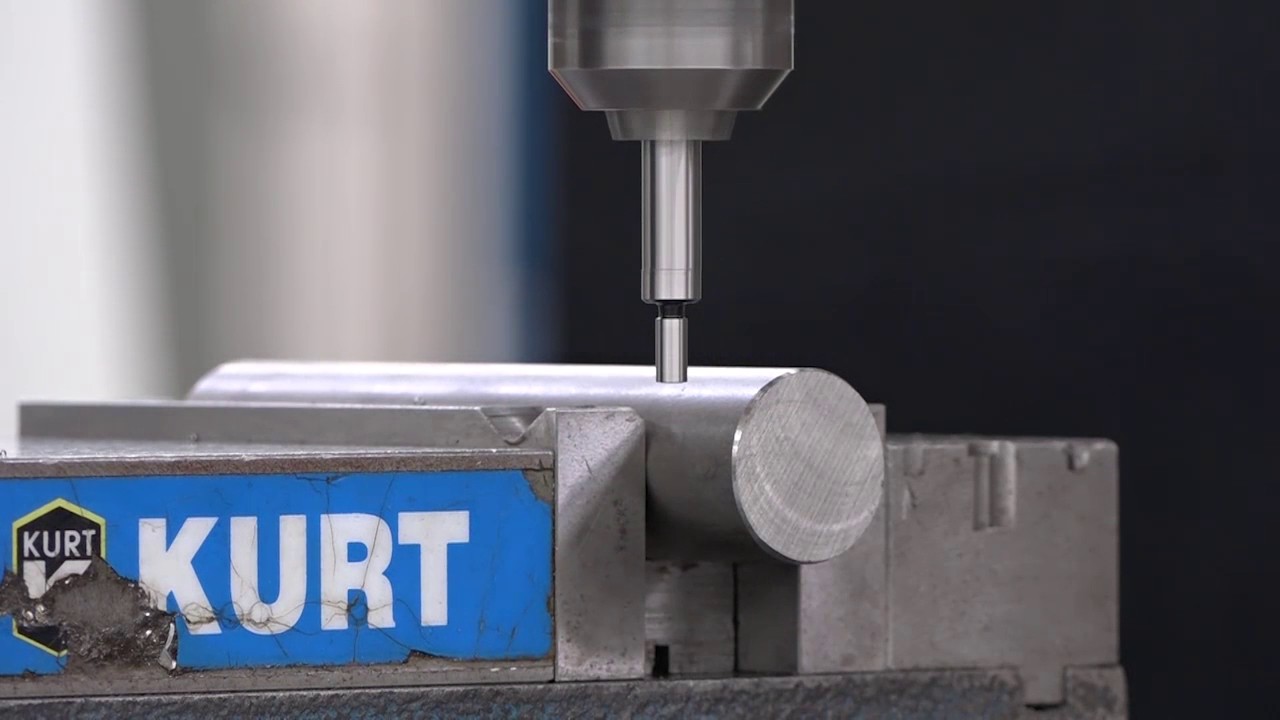

Old Machinists Mill Trick To Quickly Find a Rod Centerline

Images related to the topicOld Machinists Mill Trick To Quickly Find a Rod Centerline

How do lathes hold round stock?

One of the best ways to hold round stock in the lathe is to bore the diameter of your round stock into a set of soft lathe jaws. To do this you’ll need to change the hard jaws of your lathe chuck to soft machinable jaws. A “plug” or peice of small round stock will be needed to create a positive clamping situation.

What is the most common workholding device?

> Chucks – Chucks are probably the most widely adopted type of workholding device on the lathe. They are efficient and accurate and work well with most types of workpieces. Chucks can be divided into four main types: Three Jaw Chucks – self-centering and hold regular shapes, such as round or hexagonal workpieces.

What are the work holding devices in milling machine?

- Circular Table.

- Collets.

- T-bolts and Clamps.

- Angle Plates.

- Parallels.

- Fixtures.

- Cutter Holding Devices.

- Direct Mounting to the Table.

Which part of the lathe holds the workpiece?

(i) Chuck. It is that part of the lathe machine which is used to hold the workpiece. It is attached to the main spindle of the headstock. It rotates with the spindle and also rotates the workpiece.

What are the different work holding methods on lathe machine?

- Chuck.

- Centers.

- Steady Rest.

- Carriers.

- Driving Plate.

- Face Plate.

- Mandrel.

MT12 Cutting Slots and Keyseats

Images related to the topicMT12 Cutting Slots and Keyseats

What are the tool holding devices in lathe?

- Carriers and catch plates.

- Face plates.

- Angle plates.

- Mandrels.

- Rests.

Is used for holding round job while cutting?

A mandrel is used for holding and rotating a workpiece that has a bore in it.

What type of locator has an angled interior to hold cylindrical components for milling and drilling operations?

Vises are often used to hold workpieces for milling, drilling, or grinding operations. A fixed locator that has an angled, notched interior in the shape of a “v.” V-locators are used to position and center cylindrical workpieces for milling and drilling.

What are holding devices in workshop?

Noun. 1. holding device – a device for holding something. chuck – a holding device consisting of adjustable jaws that center a workpiece in a lathe or center a tool in a drill. clamp, clinch – a device (generally used by carpenters) that holds things firmly together.

Are used for holding the milling cutters?

An arbor is a cutter holding device with a taper shank to fit the spindle taper hole of the machine; the short or long shaft end is used to mount and drive one or more cutters. having holes that fit on to the arbor. Standard milling arbors are made in three styles: A, B, and C.

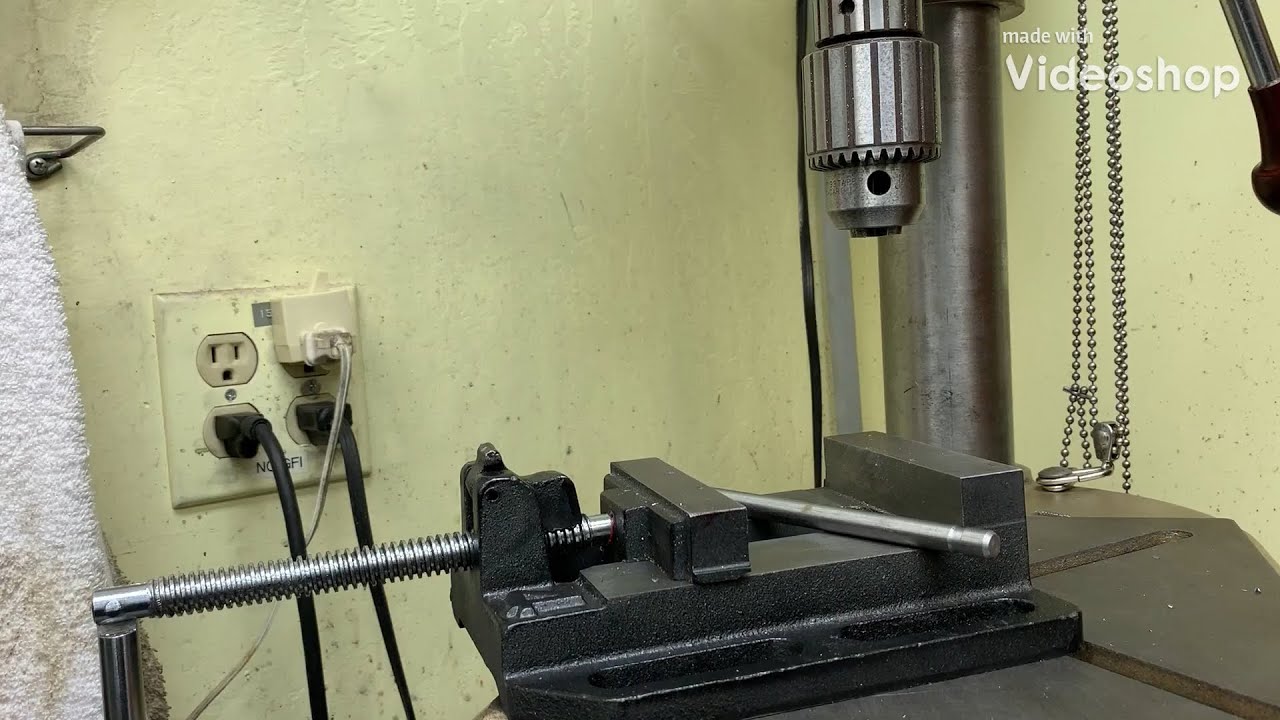

Cross drilling round stock

Images related to the topicCross drilling round stock

What is a ring clamp?

Ring Clamp. A ring clamp is extremely helpful in holding a ring or other jewelry items while filing it or mounting gems in it. The wedge shoved into the opposite end of the clamp keeps the jaws securely on the jewelry placed in them. The jaws should be leather lined to prevent marring of the jewelry.

How many types of clamps are there?

38 Types of Clamps for Every Project Imaginable (Clamp Guide)

Related searches

- how to calculate stock holding

- round stock workholding

- holding round parts in a vise

- round workholding

- how to mill round stock

- machining soft jaws

- how to sell stock from holdings in zerodha

- cnc soft jaws design

- how to find center of round stock in mill

- how to make soft jaws

- how to hold round stock in vise

- how to drill round stock

- vise jaws for round stock

Information related to the topic how to hold round stock for milling

Here are the search results of the thread how to hold round stock for milling from Bing. You can read more if you want.

You have just come across an article on the topic how to hold round stock for milling. If you found this article useful, please share it. Thank you very much.