Let’s discuss the question: how to make a reducer out of sheet metal. We summarize all relevant answers in section Q&A of website Achievetampabay.org in category: Blog Finance. See more related questions in the comments below.

How do you calculate reducer?

…

Where :

- W = Weight in Kg.

- OD1 = Large Size Outside Diameter (mm)

- OD2 = Smaller Size Outside Diameter (mm)

- t = Wall Thickness (mm)

- H = End to End Dimension (mm)

What are the two types of reducer?

There are 2 types of standard reducers available: concentric and eccentric reducers. The concentric one, which resembles a cone, is used to join pipe sections on the same axis. The eccentric type has an edge which is parallel to that of the connecting pipe, which allows it to align with one side of the inlet.

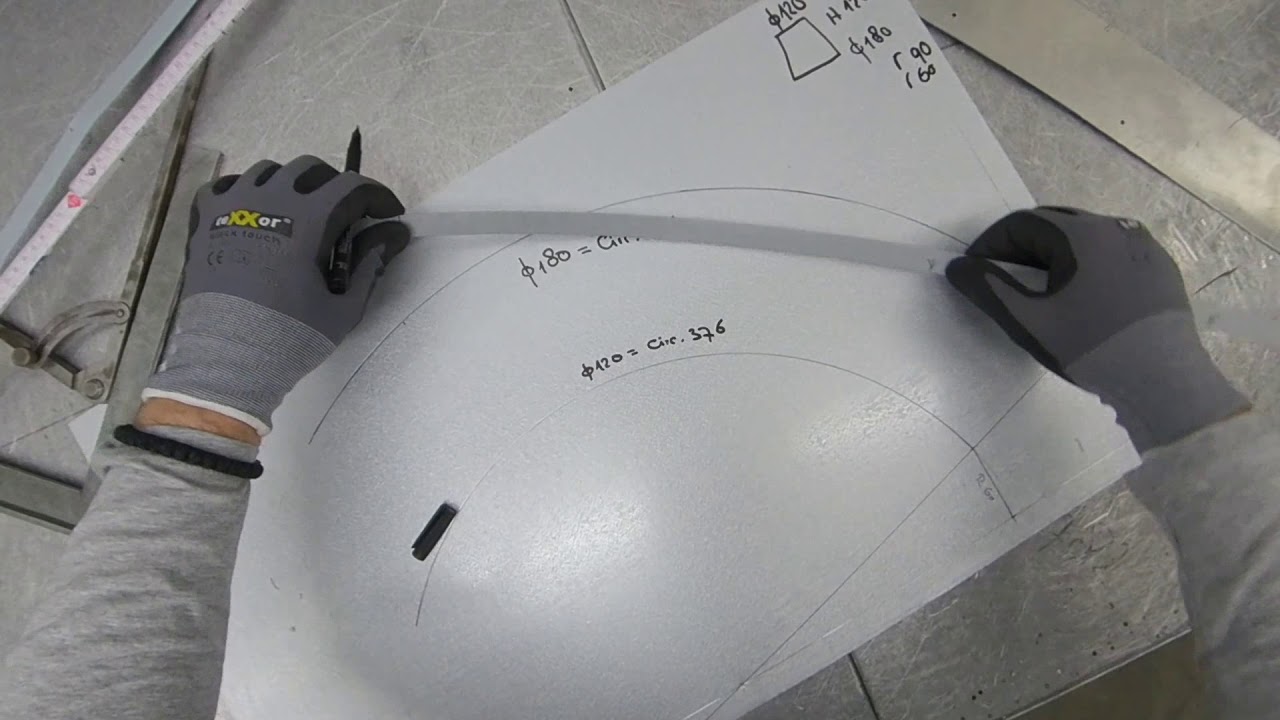

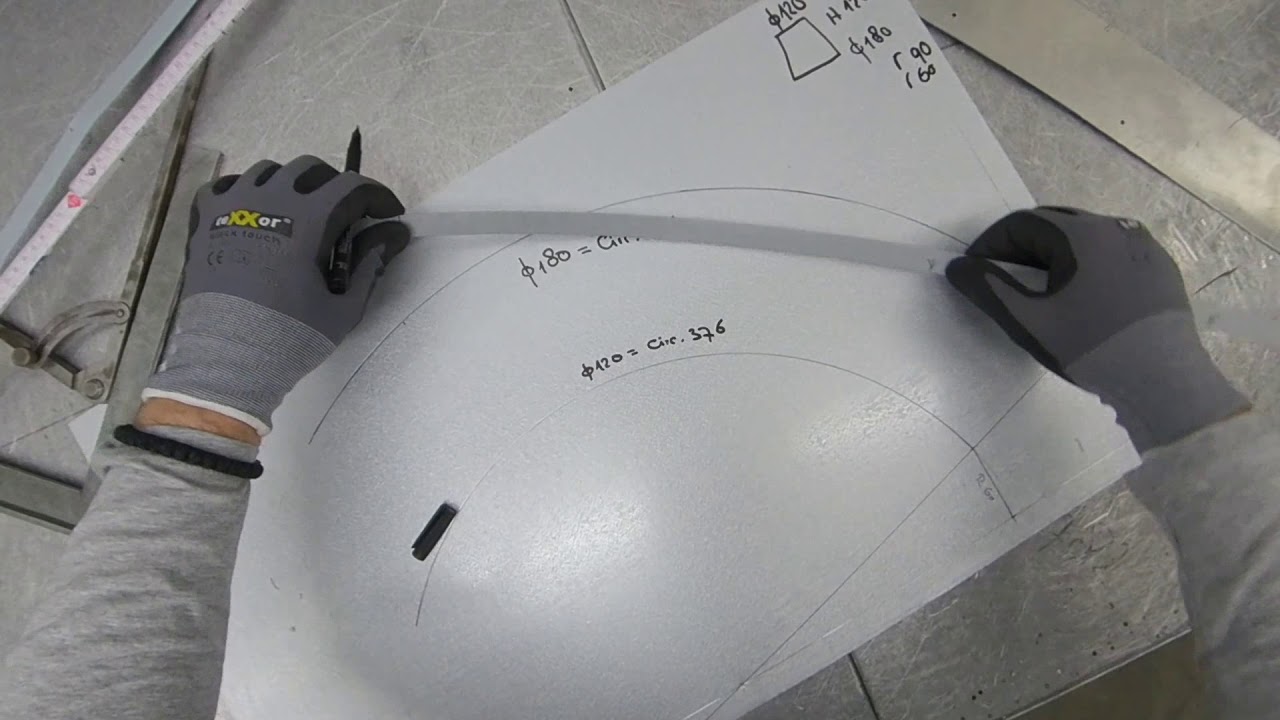

Reducer Sheet Metal

Images related to the topicReducer Sheet Metal

What is reducer material?

Pipe Reducer Material Types

The reducers can be made of Carbon Steel, Alloy, or Stainless steel and much more. In comparison to the Stainless Steel Reducer, Carbon Steel Reducer possesses high-pressure resistance, higher strength, and wear resistant but this can be easily corroded.

What do reducers do?

Reducers are functions that take the current state and an action as arguments, and return a new state result. In other words, (state, action) => newState .

How is inch dia reducer calculated?

Welding inchdia in it is: Total joints of 4″ in it = 1(pipe with flange) + 1(pipe with elbow) + 1 (it is optional – if a pipe purchased is of 6m length then you need to weld pipe to pipe to gain 12m length spool, but if pipe purchased is of 12m length then it is not required). so inch dia = 4*3 = 12.

What are pipe flanges?

The main use of flange is to connect pumps, pipes, valves, and other equipment to make a pipework system. Usually, flanges are threaded or welded, and you can connect two flanges by bolting them with gaskets and providing a seal that gives easy access to the piping system.

What is the difference between swage and reducer?

The swage nipple and reducer raw materials are different:

The raw materials of reducers is seamless steel pipes or steel plates,and the raw materials of swage nipple is round bar steel or billet steel.

How are pipe reducers made?

Most common method for manufacturing Reducers is Outer Die method. The pipe is cut and pressed in the outer die; compressing the one end of the pipe into a smaller size. This method is useful for manufacturing of small to medium size of reducers.

What is the difference between a concentric and eccentric reducer?

While this may seem complicated, it’s actually quite simple. Concentric reducers reduce the pipe in the center. So, if you’re looking at the reducer head-on, you can see the smaller section is formed in the direct center of the larger side. Eccentric reducers reduce the pipe to the side.

What is a reducer in piping?

A reducer is a component in a piping system that changes the pipe size from a larger to a smaller bore. A reducer allows for a change in pipe size to meet flow requirements or to adapt to existing piping. The length of the reduction is usually equal to the average of the larger and smaller pipe diameters.

What are the types of reducer?

Basically, reducers are available in two styles:Concentric reducers and Eccentric reducers. Concentric reducers are most commonly used, as they create less friction for the fluid flow, however, eccentric reducers are utilized when space or alignment is a concern.

Eccentric Reducer Sheet Metal

Images related to the topicEccentric Reducer Sheet Metal

What is opposite of reducer?

The opposite of a reducer is what it is. A reducer is a pipe component that connects larger diameter pipes to smaller ones. It could also mean a chemical substance used in photography to oxidize loose silver and diminish the density of a print or negative. There is no categorical antonym for this word.

What is reducer socket?

Pipe reducer are tube fittings that are widely used in a number of industries in order to providing greatest connection flexibility in connecting fractional tubes in various installations. Pipe reducer is a kind of pipe fitting that joins two pipes of different diameter.

Can I dispatch an action in reducer?

Dispatching an action within a reducer is an anti-pattern. Your reducer should be without side effects, simply digesting the action payload and returning a new state object. Adding listeners and dispatching actions within the reducer can lead to chained actions and other side effects.

Why reducer is called reducer?

The reason why a redux reducer is called a reducer is because you could “reduce” a collection of actions and an initial state (of the store) on which to perform these actions to get the resulting final state .

What will store will pass to the reducer?

The state parameter that gets passed to the reducer function has to be the current state of the application. In this case, we’re calling that our initialState because it will be the first (and current) state and nothing will precede it.

What is inch dia in piping?

Piping Fabrication – Progress Measurement (Inch Dia) In construction projects Inch Dia unit of Measure is used to measure the progress of Piping Spool fabrication. The weld joint of the pipe size is converted to the equivalent inch dia of. welding.

What is DIA in pipe?

Dia-Inch means the Size of Pipe which is Joined to another Pipe of Same Size – Say a 10″ pipe has a Dia-Inch = 10. So for Calculation/Report/Progress Purpose, When a 10″ Pipe is welded with a 10″ pipe, output is 10 Dia-Inch.

How do you calculate weld pipe length?

1 Calculating Filler Metal Consumption The number of pounds of welding electrodes or welding wire necessary to complete a given weld joint may be calculated by the formula: P = WL E Where: P = Pounds of electrode or wire required W = Weight per foot of weld metal L = Length of weld (feet) E = Deposition efficiency …

What is a reducing flange?

What is a Reducing Flange? Reducing flanges are a specialty flange that are most often used on projects that require the fitting together of different sized pipes. There are several types of reducing flanges including weld-neck reducing flanges, slip-on reducing flanges and threaded reducing flanges.

CONCENTRIC REDUCER/CONE Lay-out/Transition/Patern/conical/Paano pag layout ng Cone

Images related to the topicCONCENTRIC REDUCER/CONE Lay-out/Transition/Patern/conical/Paano pag layout ng Cone

What is flange in sheet metal?

A flange feature consists of a face and bend connected to an existing face along a straight edge. To add a flange feature, you select one or more edges, and specify the size and position of the material added.

How do you connect a pipe to a flange?

Typically flanges are welded or threaded, and two flanges are connected together by bolting them with gaskets to provide a seal that provides easy access to the piping system. These Flanges are available in various types such as slip on flanges, weld neck flanges, blind flanges, and socket weld flanges, etc.

Related searches

- how to layout a eccentric reducer

- making a sheet metal transition

- how to make a duct reducer

- how to make a cone out of sheet metal

- how to roll a cone out of sheet metal

- how to make a pipe reducer

- conical pipe reducer

- pipe reducer fabrication formula pdf

- how to make concentric reducer from plate

Information related to the topic how to make a reducer out of sheet metal

Here are the search results of the thread how to make a reducer out of sheet metal from Bing. You can read more if you want.

You have just come across an article on the topic how to make a reducer out of sheet metal. If you found this article useful, please share it. Thank you very much.